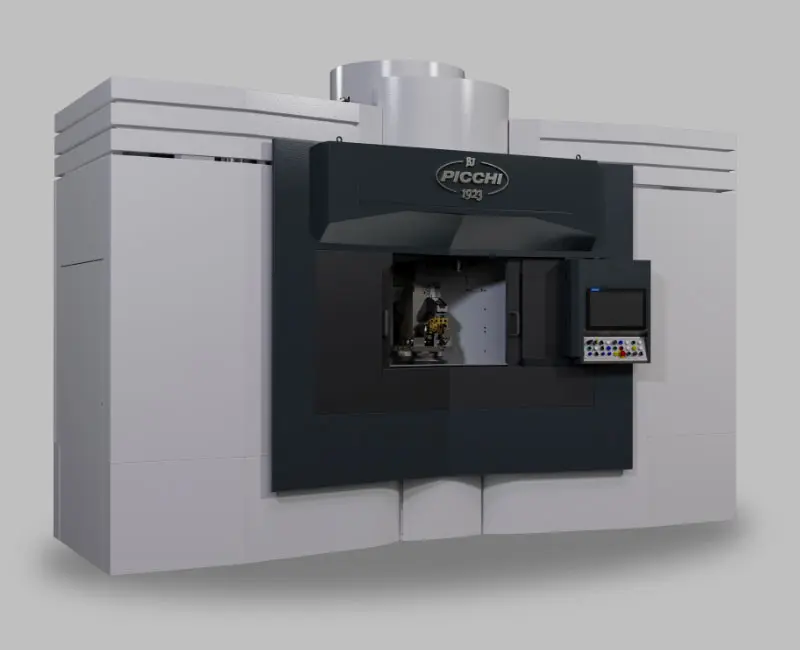

CHRONO

Horizontal CNC machining center

Chrono, multi-spindle machining center, is a modular product manufactured in series, extremely reliable and effective. We take into consideration the production needs of our clients in order to offer a solution “Turnkey” complete in each detail and verified with a test in machine.

The cycle time of the workpiece is guaranteed for a correct assessment of the productivity.

The offered equipment allows, during the execution of the item, precision and the requested flexibility.

A core element for our multicenter Chrono is the production of the piece in a trusted and accurate manner according to the productive requirements.

We propose the automation of the Chrono multi-spindle with a robot in different solutions:

Therefore:

Compared to different productive solutions, single-spindles or double-spindles machining centers, Chrono has its advantages, in addition to a very high productivity:

Having 3 spindles which work simultaneously, Chrono lowers the cycle time, and it increases the production flow, reducing the necessity of inventory in the warehouse.

Chrono, with 3 machining centers and 4 workstations, covers almost 33 sqm as for the machine itself and for its installations, the latter have a particular set which is easily accessible to the maintenance operations.

The machining centers can be equipped with a “U” axis, recess integrated, which is able to turn the external and internal outlines, thread with a single-edged tool and perform facing operations by completing the working in machine, in order to execute the piece according to the guaranteed cycle times.

The base version of Chrono has 3 or 4 machining centers linked to each other by 4 or 5 stations with continuously rotating axes.

One station is available for loading and unloading operations while the other machining centers are working. This version is for options where the cycle time is a decisive factor.

The production of complex pieces, with four axes, compels a repositioning of the item. This could not be possible because of the tolerance of the piece. To this need other advantages can be added with the presence of a fifth axis:

Founded in 1958 and headquartered in Lumezzane, Picchi is part of the Bugatti Group, of which it is the technical and technological Advisor, and from which it draws impetus for its own development.

With a 70 percent export share, it is now a benchmark in the industrial automation sector with the construction of efficient, high-precision and reliable machines.

Leave us your contact information to get more details about our Multi-spindle Machining Center.